Holomua Noiʻi ma nā Polyurethanes Non-Isocyanate

Mai ko lākou hoʻolauna ʻia ʻana i ka makahiki 1937, ua loaʻa i nā mea polyurethane (PU) nā noi nui ma nā ʻāpana like ʻole e like me ka halihali, ke kūkulu ʻana, nā petrochemicals, nā textiles, ka ʻenekinia mechanical a me ka uila, ka aerospace, ka mālama ola, a me ka mahiʻai. Hoʻohana ʻia kēia mau mea i nā ʻano e like me nā plastics foam, nā fibers, nā elastomers, nā mea pale wai, ka ʻili synthetic, nā uhi, nā mea hoʻopili, nā mea paving a me nā lako lapaʻau. Hoʻohui nui ʻia ka PU kuʻuna mai ʻelua a ʻoi aku paha nā isocyanates me nā polyols macromolecular a me nā mea hoʻolōʻihi kaulahao molekala liʻiliʻi. Eia nō naʻe, ʻo ka ʻawaʻawa kūlohelohe o nā isocyanates e hōʻike ana i nā pilikia nui i ke olakino kanaka a me ke kaiapuni; eia kekahi, loaʻa pinepine lākou mai ka phosgene - kahi mea ʻawaʻawa loa - a me nā mea maka amine e pili ana.

I ka mālamalama o ka ʻimi ʻana o ka ʻoihana kemika o kēia wā i nā hana hoʻomohala ʻōmaʻomaʻo a hoʻomau, ke kālele nui nei nā mea noiʻi i ka hoʻololi ʻana i nā isocyanates me nā kumuwaiwai aloha i ke kaiapuni ʻoiai e ʻimi ana i nā ala hana hou no nā polyurethanes non-isocyanate (NIPU). Hoʻolauna kēia pepa i nā ala hoʻomākaukau no NIPU ʻoiai e nānā ana i nā holomua i nā ʻano NIPU like ʻole a kūkākūkā i ko lākou mau manaʻolana e hiki mai ana e hāʻawi i kahi kuhikuhi no ka noiʻi hou aku.

1 Hana ʻana o nā Polyurethanes Non-Isocyanate

ʻO ka synthesis mua o nā hui carbamate kaumaha haʻahaʻa me ka hoʻohana ʻana i nā monocyclic carbonates i hui pū ʻia me nā aliphatic diamines i hana ʻia ma nā ʻāina ʻē i nā makahiki 1950—e hōʻailona ana i kahi manawa koʻikoʻi i ka synthesis polyurethane non-isocyanate. I kēia manawa aia ʻelua mau ʻano hana mua no ka hana ʻana iā NIPU: ʻO ka mea mua e pili ana i nā hopena hoʻohui stepwise ma waena o nā binary cyclic carbonates a me nā binary amines; ʻo ka lua e pili ana i nā hopena polycondensation e pili ana i nā diurethane intermediates me nā diols e hoʻomaʻamaʻa i nā hoʻololi hoʻonohonoho i loko o nā carbamates. Hiki ke loaʻa nā Diamarboxylate intermediates ma o nā ala cyclic carbonate a i ʻole dimethyl carbonate (DMC); ma ke kumu, hana nā ʻano hana āpau ma o nā hui waikawa carbonic e hāʻawi ana i nā hana carbamate.

Hoʻākāka nā ʻāpana ma lalo nei i ʻekolu mau ʻano like ʻole no ka hana ʻana i ka polyurethane me ka hoʻohana ʻole ʻana i ka isocyanate.

1.1 Alanui Carbonate Cyclic Binary

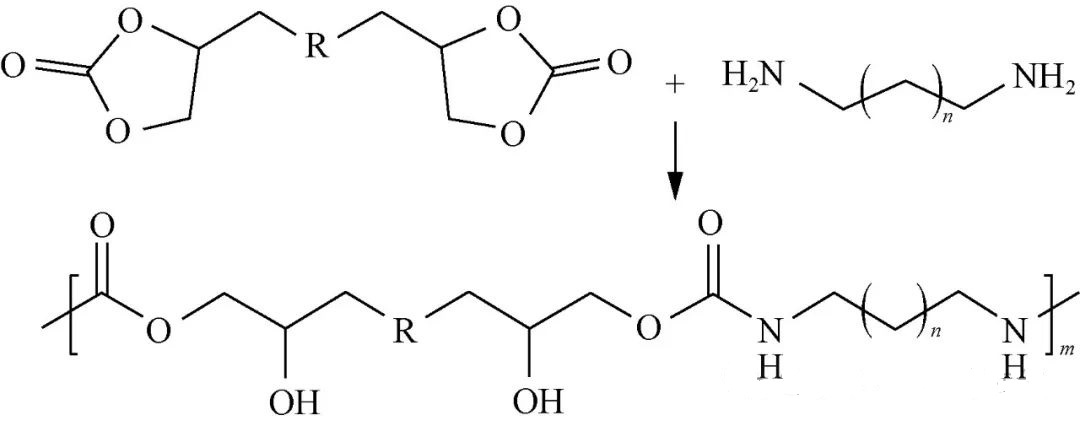

Hiki ke hoʻohui ʻia ʻo NIPU ma o nā hoʻohui ʻanuʻu e pili ana i ka binary cyclic carbonate i hui pū ʻia me ka binary amine e like me ka mea i hōʻike ʻia ma ke Kiʻi 1.

Ma muli o nā hui hydroxyl he nui i loko o nā ʻāpana hana hou ma kona ʻano kaulahao nui, ʻo kēia ʻano hana e hua mai i ka mea i kapa ʻia ʻo polyβ-hydroxyl polyurethane (PHU). Ua hoʻomohala ʻo Leitsch et al., i kahi moʻo o nā polyether PHU e hoʻohana ana i nā polyethers i hoʻopau ʻia me ka cyclic carbonate me nā binary amines a me nā mole liʻiliʻi i loaʻa mai nā binary cyclic carbonates—e hoʻohālikelike ana i kēia mau mea me nā ʻano kuʻuna i hoʻohana ʻia no ka hoʻomākaukau ʻana i nā polyether PU. Ua hōʻike kā lākou mau ʻike ua hana maʻalahi nā hui hydroxyl i loko o nā PHU i nā pilina hydrogen me nā ʻātoma nitrogen/oxygen i loko o nā ʻāpana palupalu/paʻakikī; hoʻopilikia pū nā ʻokoʻa ma waena o nā ʻāpana palupalu i ke ʻano o ka hoʻopaʻa ʻana o ka hydrogen a me nā kekelē hoʻokaʻawale microphase e hoʻopilikia ai i nā ʻano hana holoʻokoʻa.

ʻO ka maʻamau, hana ʻia ma lalo o nā mahana i ʻoi aku ma mua o 100 °C, ʻaʻole hana kēia ala i nā huahana ʻaoʻao i ka wā o nā kaʻina hana e hana ana i mea ʻole i ka makū ʻoiai e loaʻa ana nā huahana paʻa me ka ʻole o nā hopohopo volatility akā naʻe e pono ai nā mea hoʻoheheʻe organik i hōʻailona ʻia e ka polarity ikaika e like me dimethyl sulfoxide (DMSO), N, N-dimethylformamide (DMF), etc. Eia kekahi, ʻo ka hoʻonui ʻia o nā manawa hana mai hoʻokahi lā a hiki i ʻelima mau lā e loaʻa pinepine ai nā kaumaha molekala haʻahaʻa e hāʻule pinepine ana ma lalo o nā paepae ma kahi o 30k g/mol e hana ana i ka hana nui ʻana i mea paʻakikī ma muli o ke kumu nui o nā kumukūʻai kiʻekiʻe e pili ana i laila me ka ikaika lawa ʻole i hōʻike ʻia e nā PHU hopena ʻoiai nā noi hoʻohiki e pili ana i nā wahi mea damping shape memory constructs adhesive formulations coating solutions foams etc.

1.2 Alanui Monocylic Carbonate

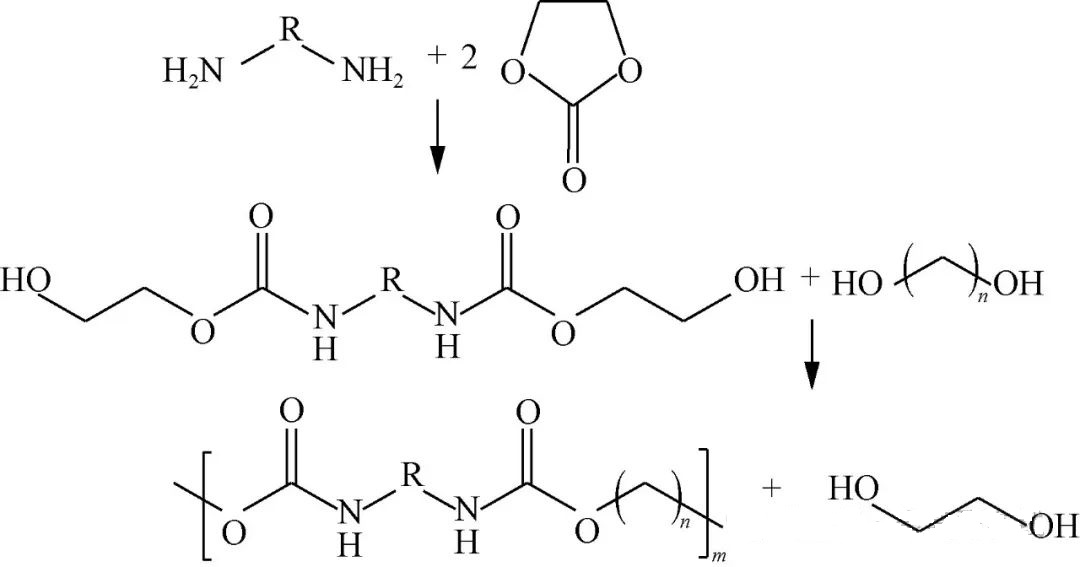

Hoʻopili pololei ka monocylic carbonate me ka diamine e hopena ana i ka dicarbamate nona nā hui hopena hydroxyl a laila e hana ana i nā pilina transesterification / polycondensation kūikawā me nā diols e hana hope ana i kahi NIPU e like me ke ʻano kuʻuna i hōʻike ʻia ma o ke Kiʻi 2.

ʻO nā ʻano monocylic i hoʻohana pinepine ʻia e komo pū me nā substrates ethylene & propylene carbonated kahi i hoʻohana ai ka hui o Zhao Jingbo ma ke Kulanui Kemika o Beijing i nā diamines like ʻole e pane ana iā lākou e kūʻē i nā hui cyclical i ʻōlelo ʻia i ka wā mua e loaʻa ana nā mea waena dicarbamate structural like ʻole ma mua o ka hoʻomau ʻana i nā pae condensation me ka hoʻohana ʻana i ka polytetrahydrofuranediol/polyether-diols e hoʻopau ana i ka hoʻokumu holomua ʻana o nā laina huahana e hōʻike ana i nā waiwai thermal/mechanical kupaianaha e hiki ana i nā kiko heheʻe i luna e lele ana a puni ka laulā e hoʻonui ana i ka ikaika tensile ma kahi o 125 ~ 161 ° C e piʻi ana ma kahi o 24MPa elongation rates kokoke i 1476%. Wang et al., ua hoʻohana like i nā hui pū ʻana me DMC i hui pū ʻia me nā precursors hexamethylenediamine/cyclocarbonated synthesizing hydroxy-terminated derivatives ma hope i hoʻokomo ʻia nā waikawa dibasic biobased e like me oxalic/sebacic/acids adipic-acid-terephtalics e hoʻokō ana i nā hopena hope loa e hōʻike ana i nā pae e pili ana i 13k ~ 28k g / mol tensile strengths fluctuating9 ~ 17 MPa elongations varying35% ~ 235%.

Hoʻopili pono nā esters Cyclocarbonic me ka ʻole o ka koi ʻana i nā catalysts ma lalo o nā kūlana maʻamau e mālama ana i nā mahana wela ma kahi o 80° a 120°C, hoʻohana pinepine nā transesterifications ma hope i nā ʻōnaehana catalytic organotin e hōʻoiaʻiʻo ana i ka hana maikaʻi loa ʻaʻole e ʻoi aku ma mua o 200°. Ma waho aʻe o nā hana condensation wale nō e kuhikuhi ana i nā mea hoʻokomo diolic hiki ke hoʻohuihui ponoʻī / deglycolysis i nā hanana e kōkua ana i ka hana ʻana i nā hopena i makemake ʻia e hāʻawi i ke ʻano hana i ka eco-friendly e hāʻawi nui ana i nā koena methanol / mole liʻiliʻi-diolic e hōʻike ana i nā koho ʻoihana kūpono e neʻe ana i mua.

Alanui 1.3Dimethyl Carbonate

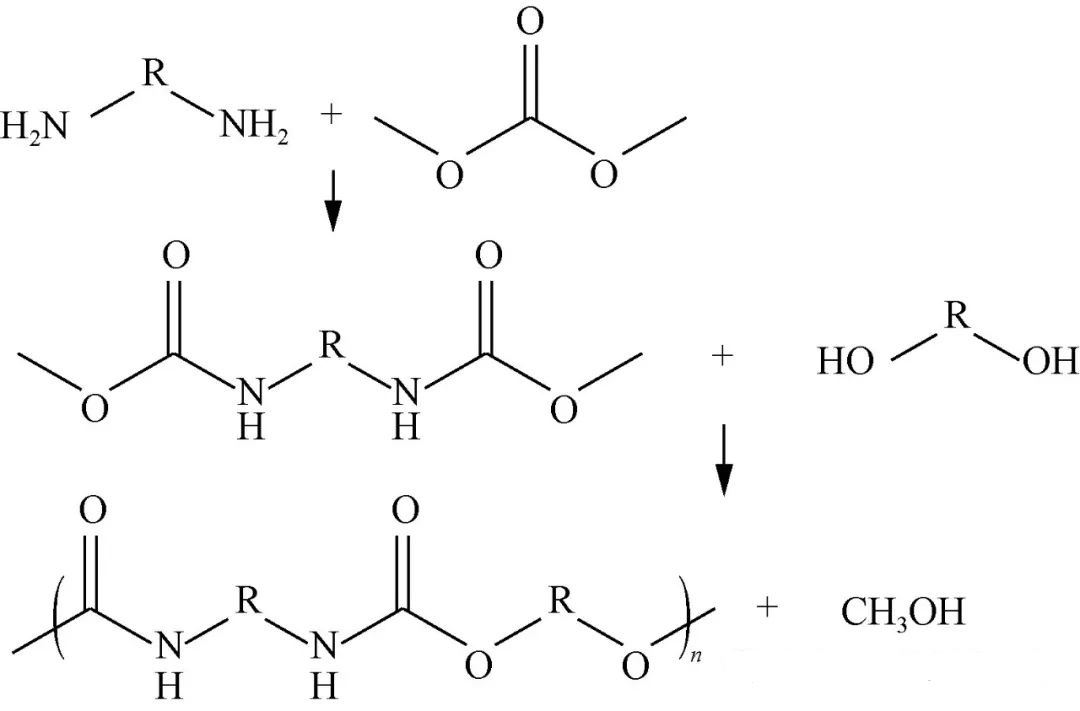

Hōʻike ʻo DMC i kahi koho ʻē aʻe kūpono i ke kaiapuni/ʻaʻohe ʻawaʻawa e hōʻike ana i nā ʻāpana hana he nui e komo pū ana me nā hoʻonohonoho methyl/methoxy/carbonyl e hoʻonui ana i nā ʻano reactivity e hiki ai ke hoʻopili pololei i nā hana mua kahi e launa pū ai ʻo DMC me nā diamines e hana ana i nā mea waena liʻiliʻi i hoʻopau ʻia me ka methyl-carbamate ma hope o nā hana hoʻoheheʻe-hoʻoheheʻe e hoʻokomo ana i nā ʻāpana liʻiliʻi-chain-extender-diolics/polyol nui aʻe e alakaʻi ana i ka puka ʻana mai o nā ʻano polymer i ʻimi ʻia i ʻike ʻia ma o ke Kiʻi 3.

Ua hoʻohana ʻo Deepa et.al i nā dynamics i ʻōlelo ʻia ma luna nei e hoʻohana ana i ka sodium methoxide catalysis e hoʻonohonoho ana i nā ʻano waena like ʻole ma hope o ka hoʻopili ʻana i nā hoʻonui i kuhikuhi ʻia e hoʻopau ana i nā ʻano hana like ʻole o ka ʻāpana paʻakikī e loaʻa ana nā kaumaha molekala kokoke (3 ~ 20) x10 ^ 3g / mol nā mahana hoʻololi aniani e uhi ana (-30 ~ 120 ° C). Ua koho ʻo Pan Dongdong i nā hui hoʻolālā e pili ana i ka DMC hexamethylene-diaminopolycarbonate-polyalcohols e hoʻokō ana i nā hopena koʻikoʻi e hōʻike ana i nā metrika ikaika tensile e oscillating10-15MPa elongation ratios approaching1000% -1400%. Ua hōʻike nā noiʻi e pili ana i nā mana hoʻolōʻihi kaulahao like ʻole i nā makemake e hoʻohālikelike maikaʻi i nā koho butanediol / hexanediol i ka wā i mālama ai ka parity helu atomika i ka like e hoʻolaha ana i nā hoʻonui crystallinity i kauoha ʻia i ʻike ʻia ma nā kaulahao. Ua hoʻomākaukau ka hui ʻo Sarazin i nā composites e hoʻohui ana i ka lignin / DMC me ka hexahydroxyamine e hōʻike ana i nā ʻano mechanical kūpono ma hope o ka hana ʻana ma 230 ℃. Ua manaʻo ʻia nā noiʻi hou e loaʻa nā non-isocyante-polyureas e hoʻohana ana i ka hoʻopili ʻana o ka diazomonomer e manaʻo ana i nā noi pena hiki ke puka mai nā pono hoʻohālikelike ma luna o nā hoa vinyl-carbonaceous e hōʻike ana i ke kumukūʻai-effectiveness / ākea o nā ala sourcing. ʻO ka noiʻi pono e pili ana i nā ʻano hana bulk-synthesized e koi pinepine i nā wahi mahana kiʻekiʻe / vacuum e hōʻole ana i nā koi solvent no laila e hoʻemi ana i nā kahawai ʻōpala i kaupalena nui ʻia nā methanol / small-molecule-diolic effluents e hoʻokumu ana i nā paradigms syntheses ʻōmaʻomaʻo holoʻokoʻa.

2 Nā ʻāpana palupalu like ʻole o ka polyurethane non-isocyanate

2.1 Polyether polyurethane

Hoʻohana nui ʻia ka Polyether polyurethane (PEU) ma muli o kona ikehu cohesion haʻahaʻa o nā pilina ether i nā ʻāpana hana hou ʻāpana palupalu, maʻalahi ka hoʻohuli ʻana, ka maʻalahi o ka mahana haʻahaʻa maikaʻi loa a me ke kūpaʻa hydrolysis.

Ua hana ʻo Kebir et al. i ka polyether polyurethane me DMC, polyethylene glycol a me ka butanediol ma ke ʻano he mau mea maka, akā ua haʻahaʻa ke kaumaha molekala (7 500 ~ 14 800g/mol), ua haʻahaʻa ʻo Tg ma mua o 0 ℃, a ua haʻahaʻa hoʻi ke kiko heheʻe (38 ~ 48 ℃), a ua paʻakikī ka ikaika a me nā ʻōkuhi ʻē aʻe e hoʻokō i nā pono o ka hoʻohana. Ua hoʻohana ka hui noiʻi a Zhao Jingbo i ka ethylene carbonate, 1, 6-hexanediamine a me ka polyethylene glycol e hana i ka PEU, nona ke kaumaha molekala o 31 000g/mol, ka ikaika tensile o 5 ~ 24MPa, a me ka elongation ma ka haki o 0.9% ~ 1 388%. ʻO ke kaumaha molekala o ka moʻo synthesized o nā polyurethanes ʻala he 17 300 ~ 21 000g/mol, ʻo ka Tg he -19 ~ 10 ℃, ʻo ke kiko heheʻe he 102 ~ 110 ℃, ʻo ka ikaika tensile he 12 ~ 38MPa, a ʻo ka helu hoʻōla elastic o 200% elongation mau he 69% ~ 89%.

Ua hoʻomākaukau ka hui noiʻi o Zheng Liuchun lāua ʻo Li Chuncheng i ka 1, 6-hexamethylenediamine (BHC) waena me ka dimethyl carbonate a me 1, 6-hexamethylenediamine, a me ka polycondensation me nā mole liʻiliʻi like ʻole o nā diols kaulahao pololei a me nā polytetrahydrofuranediols (Mn=2 000). Ua hoʻomākaukau ʻia kahi moʻo o nā polyether polyurethanes (NIPEU) me ke ala non-isocyanate, a ua hoʻoponopono ʻia ka pilikia crosslinking o nā waena i ka wā o ka hopena. Ua hoʻohālikelike ʻia ke ʻano a me nā waiwai o ka polyether polyurethane kuʻuna (HDIPU) i hoʻomākaukau ʻia e NIPEU a me 1, 6-hexamethylene diisocyanate, e like me ka mea i hōʻike ʻia ma ka Papa 1.

| Laʻana | ʻĀpana nuipaʻa ʻāpana paʻakikī/% | Kaumaha molekole/(g·mol^(-1)) | ʻIkepili hoʻolaha kaumaha molekala | Ikaika tensile/MPa | Elongation i ka wā haki/% |

| NIPEU30 | 30 | 74000 | 1.9 | 12.5 | 1250 |

| NIPEU40 | 40 | 66000 | 2.2 | 8.0 | 550 |

| HDIPU30 | 30 | 46000 | 1.9 | 31.3 | 1440 |

| HDIPU40 | 40 | 54000 | 2.0 | 25.8 | 1360 |

Papa 1

Hōʻike nā hopena ma ka Papa 1 ʻo nā ʻokoʻa kūkulu ma waena o NIPEU a me HDIPU ma muli nui o ka ʻāpana paʻakikī. ʻO ka hui urea i hana ʻia e ka hopena ʻaoʻao o NIPEU ua hoʻokomo hewa ʻia i loko o ke kaulahao molekala ʻāpana paʻakikī, e uhaʻi ana i ka ʻāpana paʻakikī e hana i nā pilina hydrogen i kauoha ʻia, e hopena ana i nā pilina hydrogen nāwaliwali ma waena o nā kaulahao molekala o ka ʻāpana paʻakikī a me ka crystallinity haʻahaʻa o ka ʻāpana paʻakikī, e hopena ana i ka hoʻokaʻawale haʻahaʻa o NIPEU. ʻO ka hopena, ʻoi aku ka ʻino o kona mau waiwai mechanical ma mua o HDIPU.

2.2 Polyester Polyurethane

ʻO ka Polyester polyurethane (PETU) me nā polyester diols ma ke ʻano he mau ʻāpana palupalu he biodegradability maikaʻi, biocompatibility a me nā waiwai mechanical, a hiki ke hoʻohana ʻia e hoʻomākaukau i nā scaffolds ʻenekinia kiko, he mea biomedical me nā manaʻolana noi nui. ʻO nā polyester diols i hoʻohana pinepine ʻia i nā ʻāpana palupalu he polybutylene adipate diol, polyglycol adipate diol a me polycaprolactone diol.

Ma mua, ua hoʻopili ʻo Rokicki et al. i ka ethylene carbonate me ka diamine a me nā diols like ʻole (1, 6-hexanediol,1, 10-n-dodecanol) e loaʻa ai nā NIPU like ʻole, akā ʻo ka NIPU i synthesized he kaumaha molekala haʻahaʻa a me ka Tg haʻahaʻa. Ua hoʻomākaukau ʻo Farhadian et al. i ka polycyclic carbonate me ka hoʻohana ʻana i ka ʻaila hua pua nānālā ma ke ʻano he mea maka, a laila hui pū ʻia me nā polyamines bio-based, i uhi ʻia ma kahi pā, a hoʻōla ʻia ma 90 ℃ no 24 h e loaʻa ai ka thermosetting polyester polyurethane film, kahi i hōʻike i ka paʻa wela maikaʻi. Ua synthesize ka hui noiʻi o Zhang Liqun mai ke Kulanui ʻenehana o South China i kahi moʻo o nā diamines a me nā cyclic carbonates, a laila hoʻopaʻa ʻia me ka biobased dibasic acid e loaʻa ai ka biobased polyester polyurethane. Ua hoʻomākaukau ka hui noiʻi a Zhu Jin ma Ningbo Institute of Materials Research, Chinese Academy of Sciences i ka ʻāpana paʻakikī diaminodiol me ka hoʻohana ʻana i ka hexadiamine a me ka vinyl carbonate, a laila polycondensation me ka bio-based unsaturated dibasic acid e loaʻa ai kahi moʻo o ka polyester polyurethane, hiki ke hoʻohana ʻia ma ke ʻano he pena ma hope o ka hoʻōla ultraviolet [23]. Ua hoʻohana ka hui noiʻi o Zheng Liuchun lāua ʻo Li Chuncheng i ka waikawa adipic a me ʻehā mau diols aliphatic (butanediol, hexadiol, octanediol a me decanediol) me nā helu atomika kalapona like ʻole e hoʻomākaukau i nā diols polyester e like me nā ʻāpana palupalu; Ua loaʻa kahi hui o ka polyurethane polyester non-isocyanate (PETU), i kapa ʻia ma hope o ka helu o nā ʻātoma kalapona o nā diols aliphatic, ma ka hoʻoheheʻe ʻana i ka polycondensation me ka prepolymer ʻāpana paʻakikī hydroxy-sealed i hoʻomākaukau ʻia e BHC a me diols. Hōʻike ʻia nā waiwai mechanical o PETU ma ka Papa 2.

| Laʻana | Ikaika tensile/MPa | Modulus elastic/MPa | Elongation i ka wā haki/% |

| PETU4 | 6.9±1.0 | 36±8 | 673±35 |

| PETU6 | 10.1±1.0 | 55±4 | 568±32 |

| PETU8 | 9.0±0.8 | 47±4 | 551±25 |

| PETU10 | 8.8±0.1 | 52±5 | 137±23 |

Papa 2

Hōʻike nā hopena ʻo ka ʻāpana palupalu o PETU4 ka mea i loaʻa ka nui o ke kalapona carbonyl kiʻekiʻe loa, ka pilina hydrogen ikaika loa me ka ʻāpana paʻakikī, a me ke kekelē hoʻokaʻawale pae haʻahaʻa loa. Ua kaupalena ʻia ka crystallization o nā ʻāpana palupalu a me ka paʻakikī, e hōʻike ana i ka wahi heheʻe haʻahaʻa a me ka ikaika tensile, akā ʻo ka elongation kiʻekiʻe loa i ka haki.

2.3 Polycarbonate polyurethane

ʻO ka polycarbonate polyurethane (PCU), ʻoiai ke aliphatic PCU, he kūpaʻa hydrolysis maikaʻi loa, kūpaʻa oxidation, kūpaʻa biological maikaʻi a me ka biocompatibility, a he mau manaʻolana noi maikaʻi ma ke kahua o ka biomedicine. I kēia manawa, ʻo ka hapa nui o ka NIPU i hoʻomākaukau ʻia e hoʻohana i nā polyether polyols a me nā polyester polyols ma ke ʻano he mau ʻāpana palupalu, a he kakaikahi nā hōʻike noiʻi ma ka polycarbonate polyurethane.

ʻO ka polyurethane polycarbonate non-isocyanate i hoʻomākaukau ʻia e ka hui noiʻi a Tian Hengshui ma ke Kulanui ʻenehana o South China he kaumaha molekala ma mua o 50 000 g/mol. Ua aʻo ʻia ka mana o nā kūlana hopena ma ke kaumaha molekala o ka polymer, akā ʻaʻole i hōʻike ʻia kona mau waiwai mechanical. Ua hoʻomākaukau ka hui noiʻi a Zheng Liuchun lāua ʻo Li Chuncheng iā PCU me ka hoʻohana ʻana iā DMC, hexanediamine, hexadiol a me polycarbonate diols, a kapa ʻia ʻo PCU e like me ka hapa nui o ka ʻāpana hana hou ʻana o ka ʻāpana paʻakikī. Hōʻike ʻia nā waiwai mechanical ma ka Papa 3.

| Laʻana | Ikaika tensile/MPa | Modulus elastic/MPa | Elongation i ka wā haki/% |

| PCU18 | 17±1 | 36±8 | 665±24 |

| PCU33 | 19±1 | 107±9 | 656±33 |

| PCU46 | 21±1 | 150±16 | 407±23 |

| PCU57 | 22±2 | 210±17 | 262±27 |

| PCU67 | 27±2 | 400±13 | 63±5 |

| PCU82 | 29±1 | 518±34 | 26±5 |

Papa 3

Hōʻike nā hopena he kiʻekiʻe ke kaumaha molekala o PCU, a hiki i ka 6 × 104 ~ 9 × 104g / mol, kahi hoʻoheheʻe a hiki i ka 137 ℃, a me ka ikaika tensile a hiki i ka 29 MPa. Hiki ke hoʻohana ʻia kēia ʻano PCU ma ke ʻano he plastic paʻa a i ʻole he elastomer, nona kahi manaʻolana noi maikaʻi ma ke kahua biomedical (e like me nā scaffolds ʻenekinia kino kanaka a i ʻole nā mea hoʻokomo cardiovascular).

2.4 Polyurethane non-isocyanate hybrid

ʻO ka Hybrid non-isocyanate polyurethane (hybrid NIPU) ka hoʻolauna ʻana o ka epoxy resin, acrylate, silica a i ʻole nā hui siloxane i loko o ka ʻōnaehana molekala polyurethane e hana i kahi pūnaewele interpenetrating, hoʻomaikaʻi i ka hana o ka polyurethane a hāʻawi i nā hana like ʻole i ka polyurethane.

Ua hana ʻo Feng Yuelan et al. i ka ʻaila soybean epoxy bio-based me CO2 e synthesize i ka pentamonic cyclic carbonate (CSBO), a hoʻolauna i ka bisphenol A diglycidyl ether (epoxy resin E51) me nā ʻāpana kaulahao paʻa e hoʻomaikaʻi hou aku i ka NIPU i hoʻokumu ʻia e CSBO i hoʻopaʻa ʻia me ka amine. Loaʻa i ke kaulahao molekala kahi ʻāpana kaulahao lōʻihi o ka oleic acid/linoleic acid. Loaʻa iā ia nā ʻāpana kaulahao paʻa, no laila he ikaika mechanical kiʻekiʻe a me ka paʻakikī kiʻekiʻe. Ua hana pū kekahi poʻe noiʻi i ʻekolu ʻano o nā prepolymers NIPU me nā hui hopena furan ma o ka hopena wehe ʻana o ka diethylene glycol bicyclic carbonate a me diamine, a laila hana me ka polyester unsaturated e hoʻomākaukau i kahi polyurethane palupalu me ka hana ho'ōla ponoʻī, a ua hoʻokō pono i ka pono ho'ōla ponoʻī kiʻekiʻe o ka NIPU palupalu. ʻAʻole wale nā ʻano o ka NIPU Hybrid o ka NIPU maʻamau, akā hiki ke loaʻa ka hoʻopili maikaʻi ʻana, ka pale ʻana i ka waikawa a me ka alkali corrosion, ke kū'ē ʻana i ka solvent a me ka ikaika mechanical.

3 Nānā

Hoʻomākaukau ʻia ʻo NIPU me ka ʻole o ka hoʻohana ʻana i ka isocyanate ʻawahia, a ke aʻo ʻia nei i kēia manawa ma ke ʻano o ka huʻa, ka uhi ʻana, ka hoʻopili, ka elastomer a me nā huahana ʻē aʻe, a he ākea nā manaʻolana noi. Eia nō naʻe, ʻo ka hapa nui o lākou ua kaupalena ʻia i ka noiʻi hale hana, a ʻaʻohe hana nui. Eia kekahi, me ka hoʻomaikaʻi ʻana o ke kūlana ola o ka poʻe a me ka ulu mau ʻana o ke koi, ua lilo ka NIPU me kahi hana hoʻokahi a i ʻole nā hana he nui i kuhikuhi noiʻi koʻikoʻi, e like me ka antibacterial, hoʻoponopono ponoʻī, hoʻomanaʻo ʻano, pale ahi, pale wela kiʻekiʻe a pēlā aku. No laila, pono e hoʻomaopopo ka noiʻi e hiki mai ana pehea e uhaʻi ai i nā pilikia koʻikoʻi o ka ʻoihana a hoʻomau i ka ʻimi ʻana i ke kuhikuhi o ka hoʻomākaukau ʻana i ka NIPU hana.

Ka manawa hoʻouna: ʻAukake-29-2024